Automatic Bow Machine FW 2 / FW 2-XL

Fully automatic machine to produce bows in flower or star shape. The machine is equipped with two winding heads.

The machine is capable to work with plastic – or woven fabric ribbon 6.5 to 32 mm wide. Bow sizes range from 35 mm to 130 mm in diameter, version FW 2-XL up to max. approx. 160 mm.

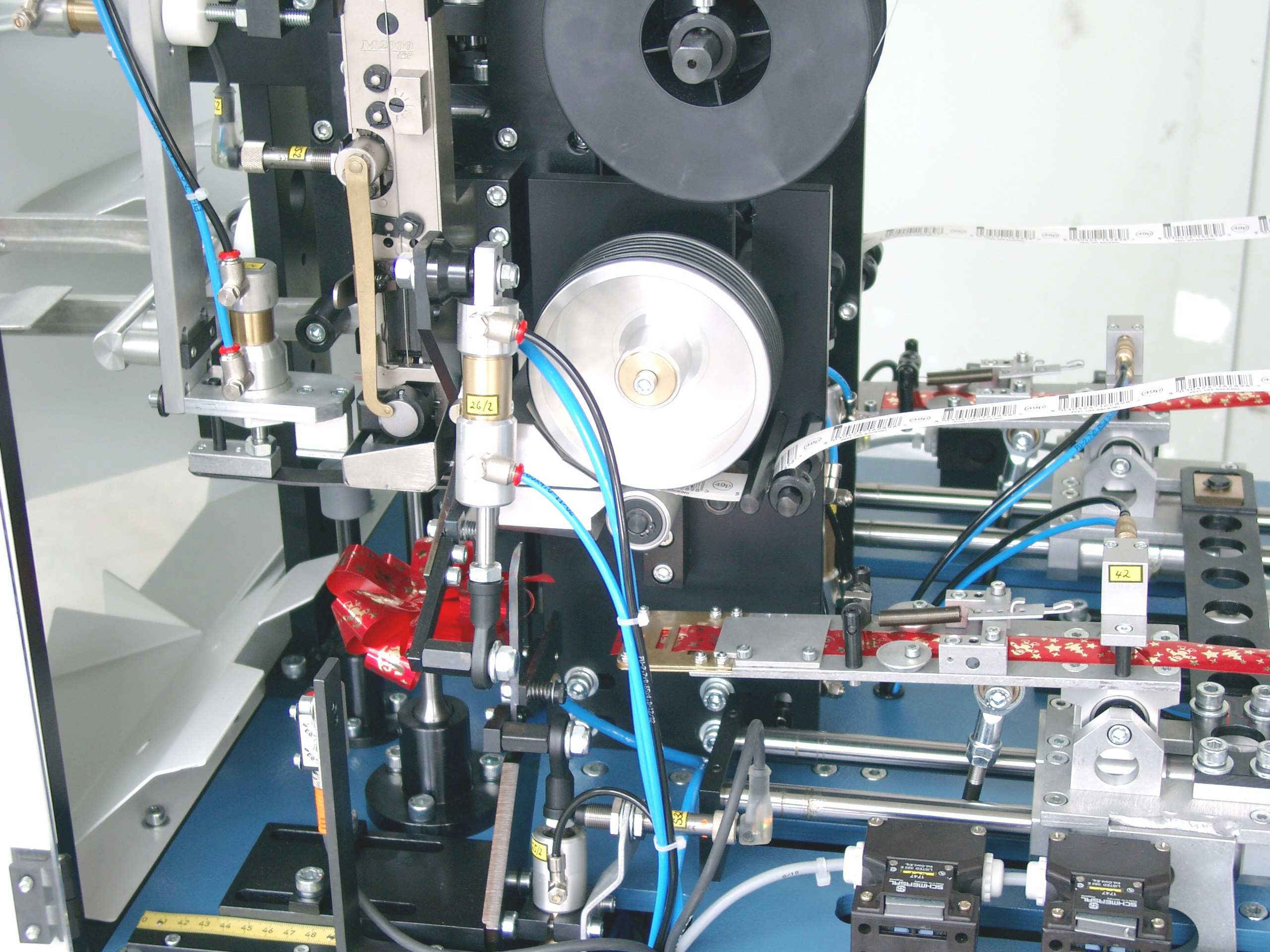

The ribbon is supplied from spools or rolls which are attached to a rack at the back side of the machine. The carrier band with the adhesive label is supplied from a roll to the winding head area. The ribbon is fed tensionless to the winding head through a compensation roll. Electronic controls combined with the disc cam controls guarantee a continued precise operation. Change of production to another bow style can be accomplished all the time precisely, reproduceable and with a minimum amount of time The ribbon is guided in the slideable mounted ribbon guiding system. The supplied material is pushed into the needles of the winding head during the downwards movement of the guiding system. Dependant on the amount of loops the winding head turns a arch, defined by the electronic controls. The ribbon guiding system moves forward again and repeats this cycle until the preset amount of loops is reached.

The carrier band with the adhesive label is supplied to the winding head. It is stitched together with the unfinished bow with a staple formed by the stitcher out of wire material during the stapling process. The ribbon is cut and the finished bow is ejected. The cycle starts again.

The operation of the machine is through a large operation panel which can be used on both sides of the machine. All machine parameters and error messages are displayed in clear language on the display.

It is possible to store up to 99 programs with all bow parameters in the operation panel.

Additional equipment

- Automatic cutting device to produce >>flowers<<.

- Production of bows with length-cutting device.

- Production of bows with two supply ribbons.

- Production of bows with long hanging label, which is at the same time the adhesive label.

- Production of bows without adhesive label.

- Production of bows with Bar-Code label.

- Ionisation device to remove the static charge of the ribbon.